Company history

In the early 1980s, the industry producing ferrites used in the manufacture of high-frequency current transformation circuits for telecommunications was looking for a state-of-the-art grinding machine to improve the quality of machined surfaces and increase productivity. These circuits also require an extremely precise air gap, so the sector called upon an engineer well known for his skill in the construction of high-performance grinding machines: Alfred Schlaefli.

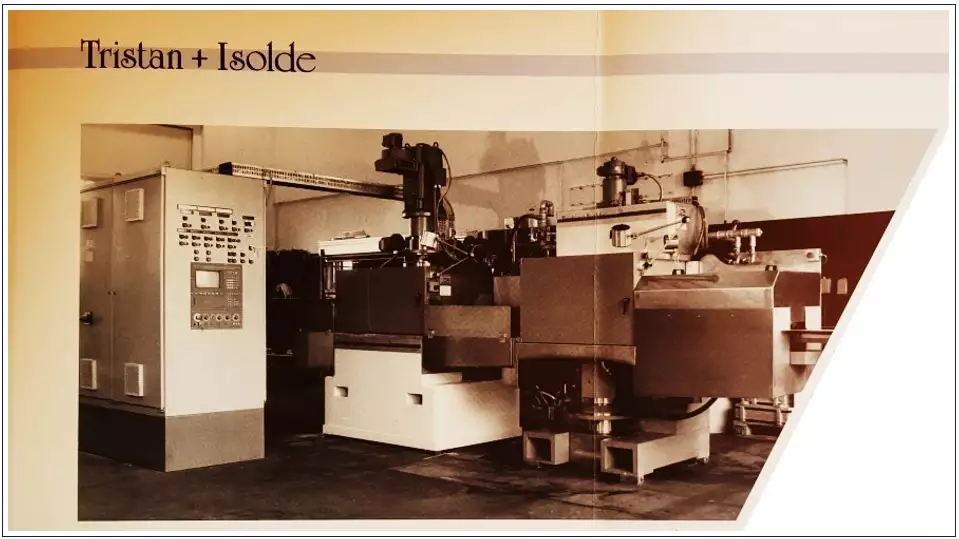

Accepting this challenge, he built the first continuous machine which combines two operations in one with a vertical and a horizontal spindle mounted on a shared cast-iron structure strengthened with reinforced concrete. The high level of rigidity obtained in this way enabled him to achieve the desired objective. This unique construction is patented in Europe and the United States of America.

In 1984, Alfred Schlaefli founded Linear Abrasive Engineering S.A., a company which he ran until 2017.

Since 2018 the company is managed by his son, Roderic, with support of a team of competent and very experienced specialists, ready to meet any challenges.

.jpg)