ISOLDE VI

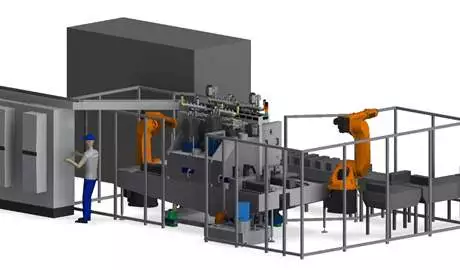

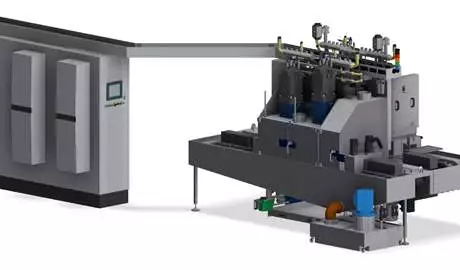

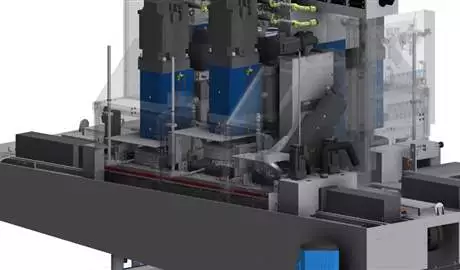

Continuous through feed grinder equipped with 4 vertical spindles and 2 tilting spindles dedicated to grinding and chamfering of silicon blocs before wafering

Performances:

Resolution 0.001 mm

High performance spindles, direct drive

Modular rigid steel frame combined with prestressed concrete

Measurement and automatic servo

Automatic, semi-automatic or manual loading

Number of spindles |

4 (surfaces)4 (chamfers) |

Number of robots |

2 |

Operations andstock removal |

rough grinding up to 1 mm/side

|

Grinding tools |

diamond wheels ø 400 mm |

Cutting speed |

up to 100 m/sec |

Production |

up to 25 blocs/h |

Quality, guaranteed |

flatness within 0.05 mmparallelisme within 0.05 mmsquarness within 0.25°thickness between 155.5 and 156.5 ± 0.03 mmsurface finish ≤ Ra 0.08 ≤ Rz 0.8 |

Documents

Spécifications techniques

- Nombre de broches 4 + 2

- Broche ø200 / 500 + AFS ø80 / 200 mm

- Axe Z 120 mm

- Vitesse de rotation 0 - 6000 rpm

- Puissance 4x 29 + 2x 5 kW

- Largeur Max. 170 mm

- Hauteur Max. 160 mm

- Outils abrasifs CBN / Diamond / Al2O3

- Meule ø400 / ø250 mm

- Avance 0 - 4000 mm/min

- Commande Siemens S7/1500/TIA

- Poids total 10 t

- Surépaisseur Max. 1 mm

- Résolution 0.001 mm