Technologies

-

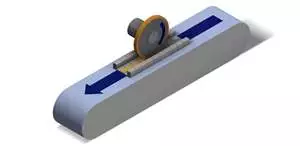

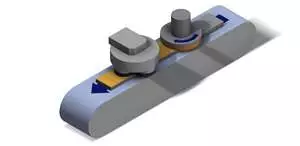

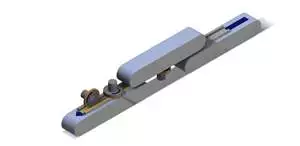

Rectification plane en continu

Méthode très productive pour usiner des surfaces en continu, utilisant des meules boisseau corindon, diamant ou CBN. Transportées par une bande synthétique très résistante, tenues par attraction magnétique (par masque ou gabarit pour pièces en matière non magnétique), les pièces guidées entre rails, défilent sous la meule. Processus maîtrisé et programme pièce assurent un rendement optimum.

Liste exhaustive de toutes les technologies dédiées à des surfaces planes maîtrisées par LINEAR ABRASIVE

Plus d'information-

1V

Rectifieuse de surface plane à 1 broche verticale

-

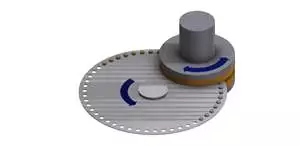

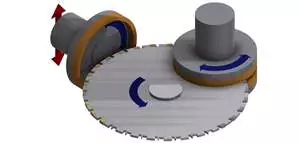

1Vb

Rectifieuse de surface plane à 1 broche verticale + 1 module de brossage planétaire

-

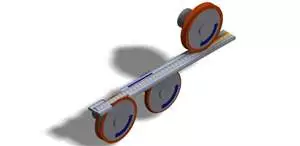

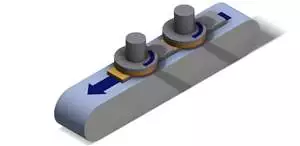

2V/V

Rectifieuse de surface plane, équipée de 2 broches verticales en opposition

-

2VH

Rectifieuse de surface plane et profil, équipée d'une broche verticale et d'une horizontale

-

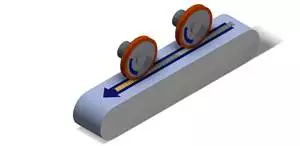

2VV

Rectifieuse de surface plane à 2 broches verticales

-

3VVH

Rectifieuse de surface plane et profilés, équipée de 2 broches verticales en opposition et 1 broche horizontale

-

3V/V H

Rectifieuse de surface plane, équipée de 2 broches verticales en opposition + 1 broche horizontale pour usiner une troisième face d'équerre

-

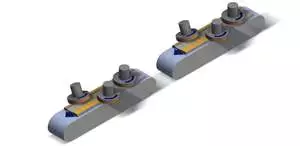

4V'V'V'V'

Rectifieuse de surfaces planes multiples

-

4VV'VV'

Rectifieuse de surfaces planes et angles, équipée de 2 broches verticales et de 2 broches à angle variable

-

4VVVH

Rectifieuse de surface plane et profils, équipée de 3 broches verticales en opposition ainsi qu'une broche horizontale

-

6VVV'VVV'

Rectifieuse de surfaces planes multiples et angles, équipée de 4 broches verticales et de 2 broches à angle variable

-

-

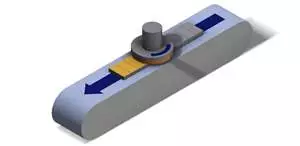

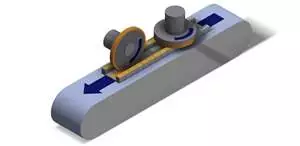

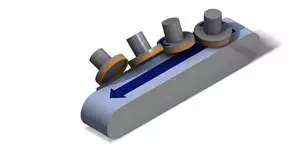

Rectification de profils en continu

Méthode très productive pour usiner des profils en continu utilisant des meules cylindriques profilées corindon, diamant ou CBN. Ce procédé permet également de tronçonner des pièces à tolérances serrées. Transportées par une bande synthétique très résistante, tenues par attraction magnétique (par masque ou gabarit pour pièces en matière non magnétique), les pièces guidées entre rails, défilent sous la meule. Processus maîtrisé et programme pièce assurent un rendement optimum.

Liste exhaustive de toutes les technologies dédiées à des surfaces profilées maîtrisées par LINEAR ABRASIVE

Plus d'information