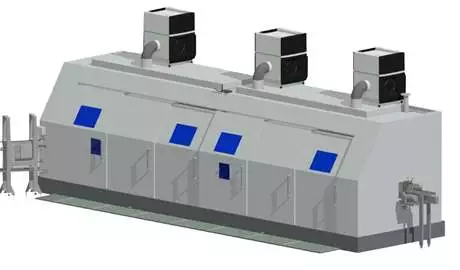

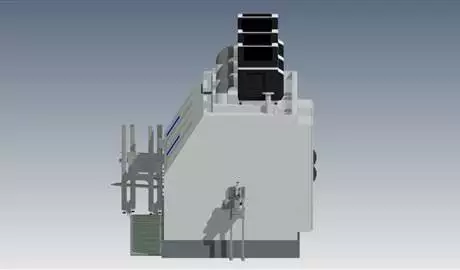

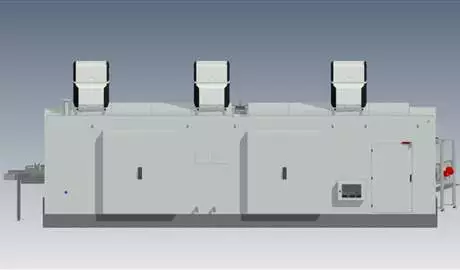

TRISTAN&ISOLDE IV

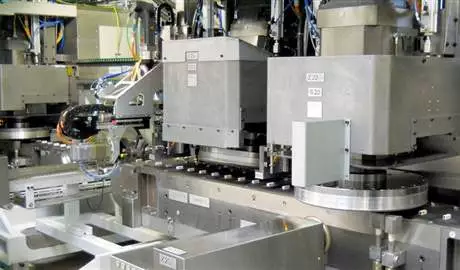

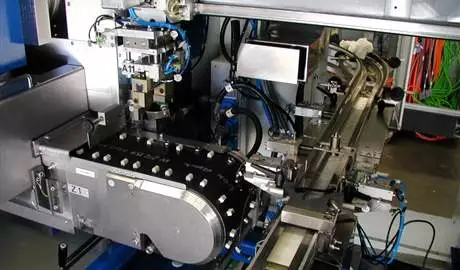

Continuous through feed grinder with 4 vertical spindles + 1 chamfer machining station. Application dedicated to machining of connecting rods

Performances

Built to produce 24/7

Grinding 6 surfaces + chamfer

Cycle time 6.5 seconds/connecting rod

Trapezoid grinding up to 8 mm in a sigle pass

Measurement and automatic servo

Designed to be integrated into automotive production lines

Resolution 0.001 mm

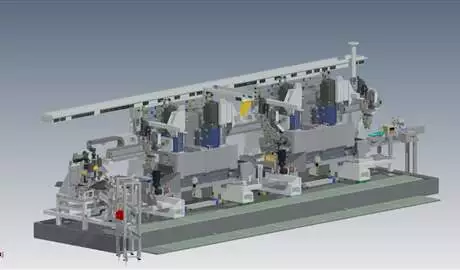

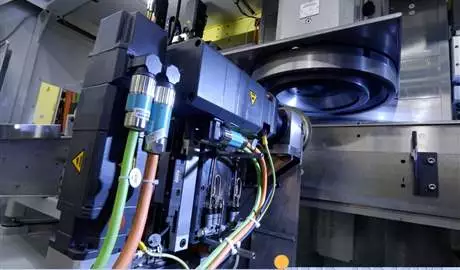

High performance spindles, direct drive

Modular rigid frame of grey cast iron combined with prestressed concrete

Loading and unloading 100% automatic

Documents

Technical specifications

- Number of spindles 4

- Spindle ø200x500 mm

- Z-axis 120 mm

- Rotation speed 0 - 3500 rpm

- Power 4x 28 kW

- Width Max. 285 mm

- Height Max. 100 mm

- Abrasive tools CBN / Diamond / Al2O3

- Grinding wheel ø500 mm

- Infeed Cycle time 6s/connecting rod

- Electrical control Siemens S7/1500/TIA

- Total weight 10 -15 t

- Stock removal Max. 8 mm

- Resolution 0.001 mm